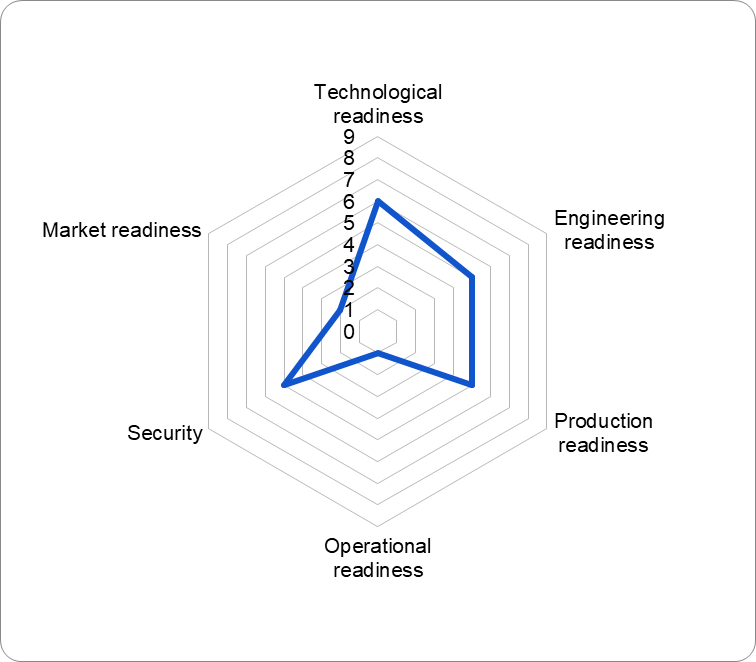

TRL-6

Ceramic vacuum seals are intended for use in mechanical engineering, energy, aerospace industry, instrument making and other industries

Market and economic attractiveness

- The proposed Typical technology for the production of metal-ceramic assemblies of hermetic guides for electron beam guns in welding and spraying installations has successfully passed the test and manufactured products

- The optimized design of metal-ceramic assemblies of hermetic conductors obtained by contact-reactive soldering technology allows to obtain products with increased thickness of current leads , which ensures increased rigidity of assemblies during operation in comparison with foreign analogues

- The operating experience of the manufactured units has shown their high reliability under thermal cycling conditions

- The developed technology has a lower cost of products by 50% compared to imported counterparts and a greater resource.

The main advantages (strengths) of the development

- The developed technology of contact-reactive soldering eliminates the need for a previous time-consuming and energy-consuming operation of metallization of ceramics (metallization of ceramics is carried out with a paste at a temperature of up to 1600 °C) with the provision of high-quality wetting of the surface of ceramic blanks with solder melt, which is formed as a result of contact-reactive interaction of its components

Main characteristics

- The developed technology can be applied to the manufacture of joints from metal and ceramics with increased quality and reliability characteristics

- The necessary vacuum density and electrical resistance of the product is provided

- A series of experimental seals for electron-beam guns, used in electron-beam installations, was produced

- The technology can be applied to the production of metal and ceramic products

- The necessary vacuum density and electrical resistance of the product is provided

Ready state

- Fully functional sample tested

- Modes of experimental production have been implemented

- Production in real conditions has been carried out

- Schemes of basic business processes are defined

- The benefits of the product are clarified

- The value proposition is formulated

Information about developers

What is needed to promote development

Customers

Comments are closed