TRL-9

Market and economic attractiveness

- The universal combustion technology “JNT” can be adapted to the customer’s requirements, the cost of work starts from 10,000 dollars . depending on the upgraded equipment. The term of design and debugging works is 3-6 months. The payback period is 0.5-2 years.

The main advantages (strengths) of the development

- In terms of their efficiency and the range of tasks to be solved, the GU JNT successfully compete with global analogues of modern gas burner equipment.

- Jet-niche type burners have been adopted as the basis for the reconstruction of Ukraine’s heating system in accordance with state energy saving programs by the Cabinet of Ministers of Ukraine and the Ministry of Housing and Communal Affairs of Ukraine.

Main characteristics

- The jet-niche technology of burning natural gas with a controlled structure of the flow of fuel and oxidizer is based on the uniform distribution of gas in the air flow without swirling the flow. A stable vortex structure is formed in the working channel of the burner, which includes circulation zones and ensures the necessary quality of mixture formation and reliable combustion stabilization. Before the fuel is burned, it is heated due to the cooling of thermally loaded areas of the burner module.

- Versatility of combustion technology: adaptation of industrial SNT burners is carried out for a wide range of fire engineering equipment for industrial and power purposes: steam and water boilers with a capacity of 0.5-125 MW , furnaces, dryers , etc.

- A high level of operational safety ( including start-up) ignition at a gas consumption of 5% of the nominal, as well as a wide range of effective operating mode (10 … 100% of the nominal power, i.e. the control factor of the object Kr > 10).

- Small hydraulic resistance along the fuel and oxidizer paths , as a result, the electric power to drive the traction equipment is reduced and the costs for own needs are reduced by 1.5-2 times.

- Environmental indicators for emissions into the atmosphere (depending on power): CNOx = 50 … 100 mg/m3 while keeping carbon monoxide emissions within regulatory limits – CСО = 0 … 55 mg/m3.

- Reduction of specific gas consumption by up to 10% when working at partial loads.

- The main advantages compared to competitors are noise reduction, ease of maintenance, adjustment and stable operation at variable gas pressure.

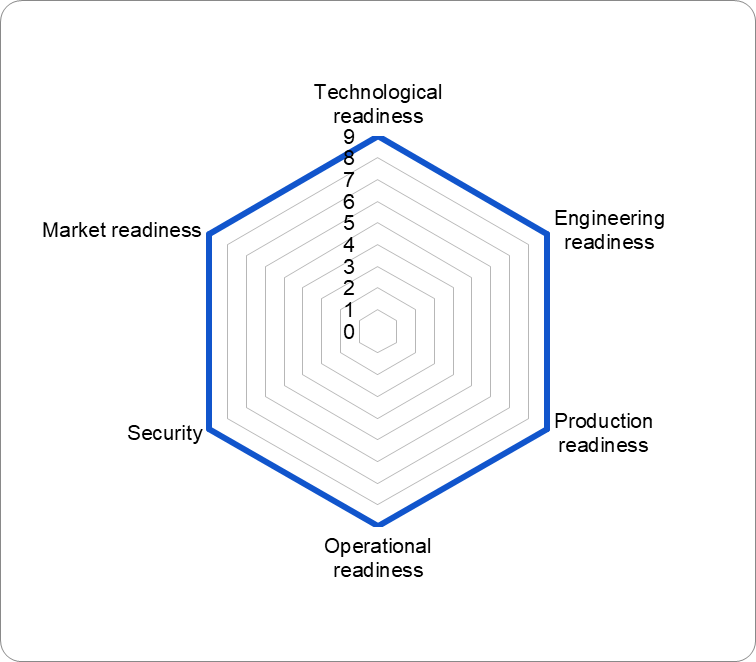

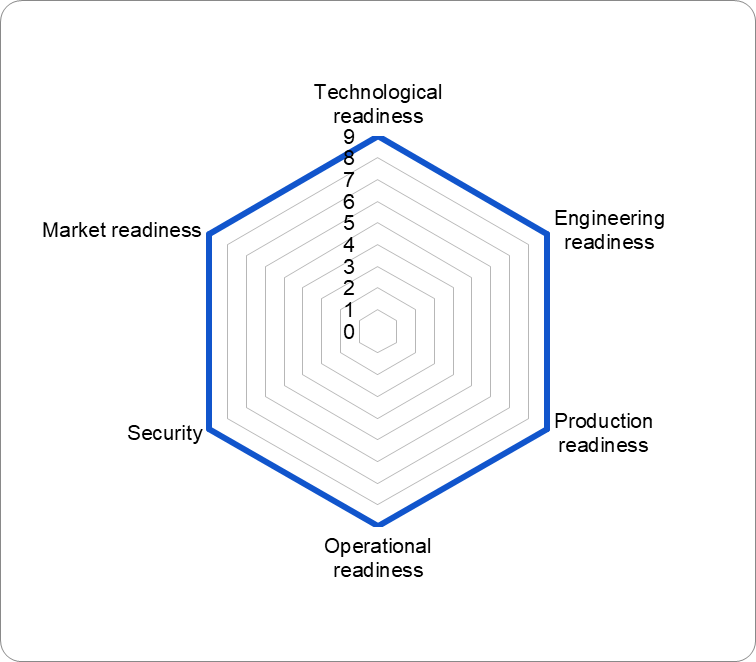

Ready state

- Improvement of own product

- The working design documentation has been checked and approved

- The main and auxiliary production is set up and working

- Support for production, service, cost reduction is taking place

- System monitoring of competitors is established

- Launching on the market took place

Information about developers

What is needed to promote development

New international contacts