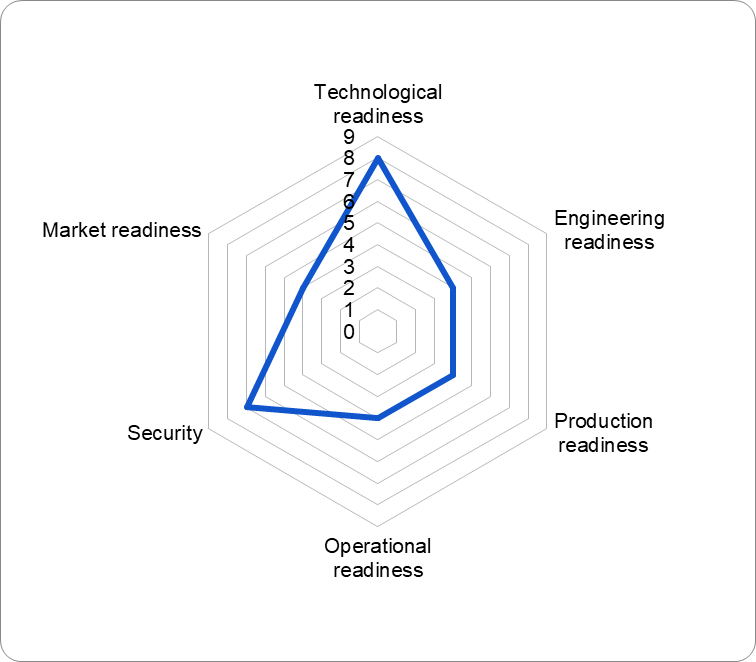

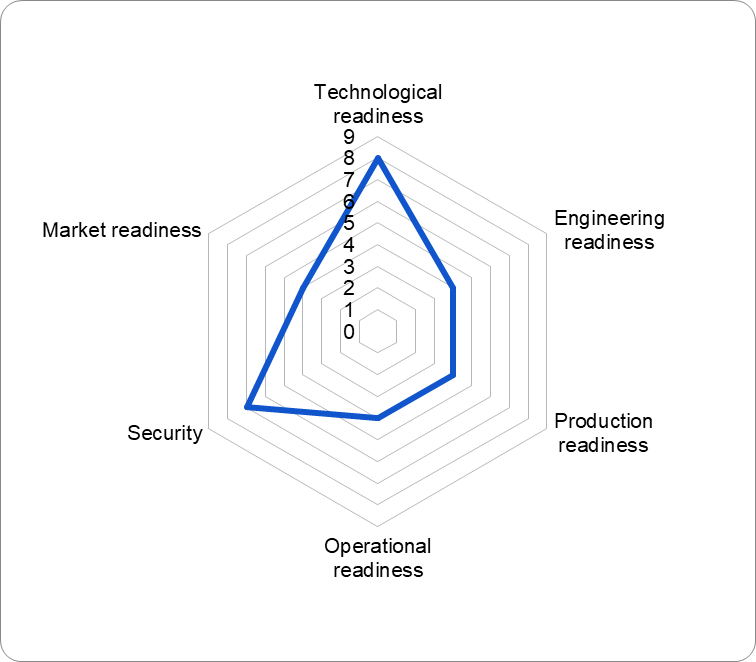

TRL-8

Market and economic attractiveness

- Implementation of the development makes it possible to extend the service life of the equipment and, as a result, the time of electricity production, as well as to reduce the repair costs of the equipment. The economic effect depends on the electric power of the power unit, its type, the nature of involvement in the power grid, current energy market tariffs, etc. For example, the extension of the operation period of a 200 MW power unit of a thermal power plant gives an economic effect of 1.7 to 3.2 million dollars per year, depending on the mode of operation in the power grid

The main advantages (strengths) of the development

- Establishing the permissible period of operation of power units allows generating companies to effectively plan their work and prevent the significant consequences of an emergency failure.

- Resource management methods significantly increase the allowable service life of the equipment. For example, the implemented technological modernizations increased the individual resource of the CVT housing of the K-800-240 turbine by 13%, modernization of the power supply scheme of the seals of the 200 MW unit by 16%, etc.

- The developed automated system of technical diagnostics allows you to set the resource indicators of the equipment online and respond quickly to deviations in operational indicators.

Main characteristics

- Determining the residual resource of energy equipment makes it possible to predict the allowable period of operation of the equipment before its transition to the limit state and is performed in accordance with the current regulatory documentation of the Ministry of Energy of Ukraine.

- The development is aimed at determining the resource indicators of power units with a capacity of 200-800 MW of thermal power plants, units of 100 and 250 MW of thermal power plants, and units of 220 and 1000 MW of nuclear power plants.

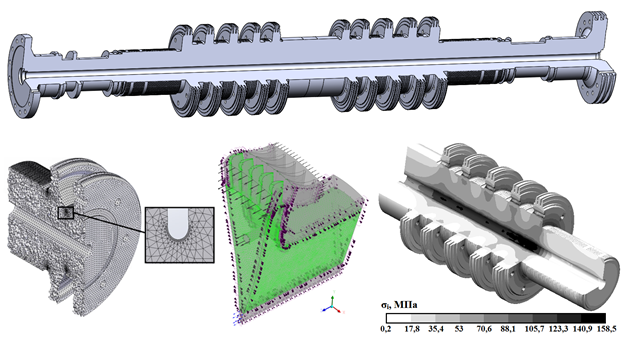

- A comprehensive assessment of the residual resource includes a technical audit of the design and operational documentation of this equipment; development of a calculation model for establishing the thermal and stress-strain states of the equipment for the most typical modes of operation; establishing the degree and rate of accumulation of equipment damage according to static and cyclic mechanisms of destruction; assessment of resource performance indicators of equipment, including permissible operating periods.

- It is possible to carry out experimental and computational studies on the implementation of resource management methods. These methods make it possible to increase the residual resource of new and existing equipment by up to 20% by performing certain structural, technological, circuit and mode modernizations.

Ready state

- The product is integrated into the system and tested

- Integration interfaces are defined

- The basic production technology has been defined and tested

- Requirements for service support are defined

- License agreements have been signed

- Suppliers and partners are identified

Information about developers

What is needed to promote development

Help in updating licensed software products