TRL-4

A gas-discharge electron gun for melting metals has been developed

Market and economic attractiveness

- The operation of gas-discharge electron guns in a low vacuum and the possibility of stable operation of the gun with active gases allows to effectively perform such complex technological operations as the application of ceramic coatings with a high stoichiometry of the chemical composition in an environment of active gases, as well as vacuum remelting of refractory metals and non-metallic materials for the purpose of their purification from harmful impurities. Such technologies are promising for use in modern electronics, in particular in nanotechnologies, in instrument building, mechanical engineering, aviation and space industry. The relatively low cost of the guns and the corresponding vacuum equipment, given the high stability of the high-voltage glow discharge guns, are also important technical and economic factors that make the high-voltage glow discharge guns very attractive from an economic point of view

The main advantages (strengths) of the development

- Electron beam guns of high-voltage glow discharge significantly differ from existing analogues in that they work stably in low and medium vacuum in the environment of various gases, in particular inert and active. Possible fields of application of such guns are high-performance electron beam welding in low vacuum, application of composite ceramic coatings with a high stoichiometry of chemical composition, and high-performance melting of refractory metals and non-metallic materials. The ability to operate guns in pulse mode expands their technological capabilities

Main characteristics

| Gun power | 10 – 500 kW |

| Cannon current | 0.1 – 20 A |

| Accelerating voltage | 10 – 30 kV |

| Working pressure | 0.1 – 10 Pa |

| Working gases | hydrogen, oxygen, nitrogen, air |

| Time of operation of the cathode without replacement | more than 1000 A/h |

| Current switching time in pulse mode | 10 – 1000 µs |

| Current switching frequency in pulse mode | 500 Hz – 5 kHz |

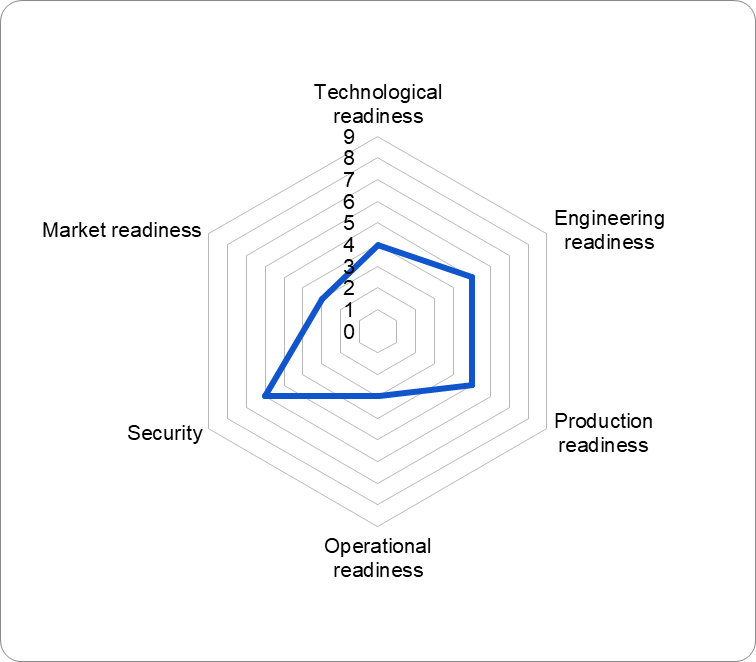

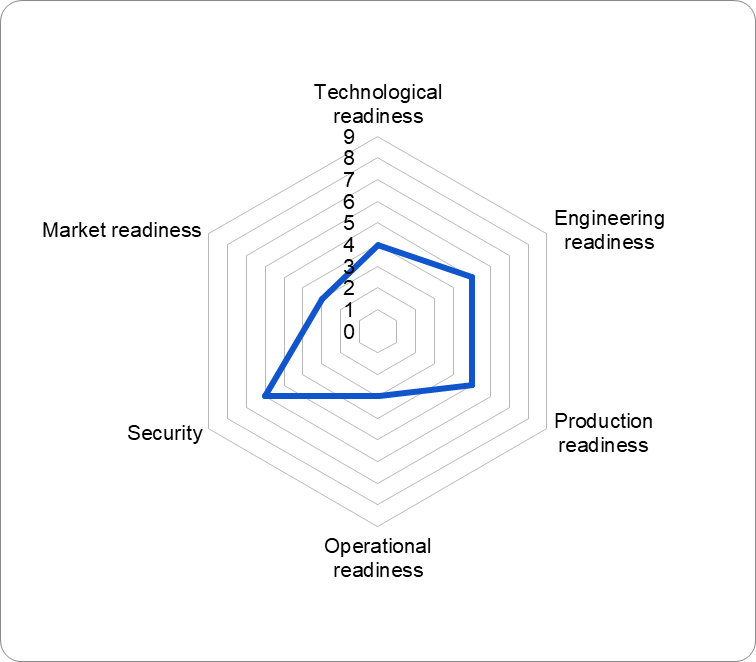

Ready state

- The laboratory sample has been tested

- Modes of experimental production have been implemented

- Production in real conditions has been carried out

- The technical requirements for the product have been clarified

- Patent applications have been submitted

- The competitive environment is defined

Information about developers

What is needed to promote development

It is necessary to know the technological conditions of using a gun in industrial production, primarily the composition and pressure of the working gas in the technological chamber