TRL-1 Development is designed for water treatment and water treatment systems, namely for membrane water treatment plants. Market and Economic Attractiveness An important component of operating costs for membrane equipment is the replacement of modules. Optimization of regeneration cycles will increase the duration of modules without replacement. At the same time, the costs of energy… Continue reading IHF-07-01. Reverse Osmosis Unit Operation Schedule with Scientifically Substantiated Determination of Operation Time Between Membrane Regeneration Cycles

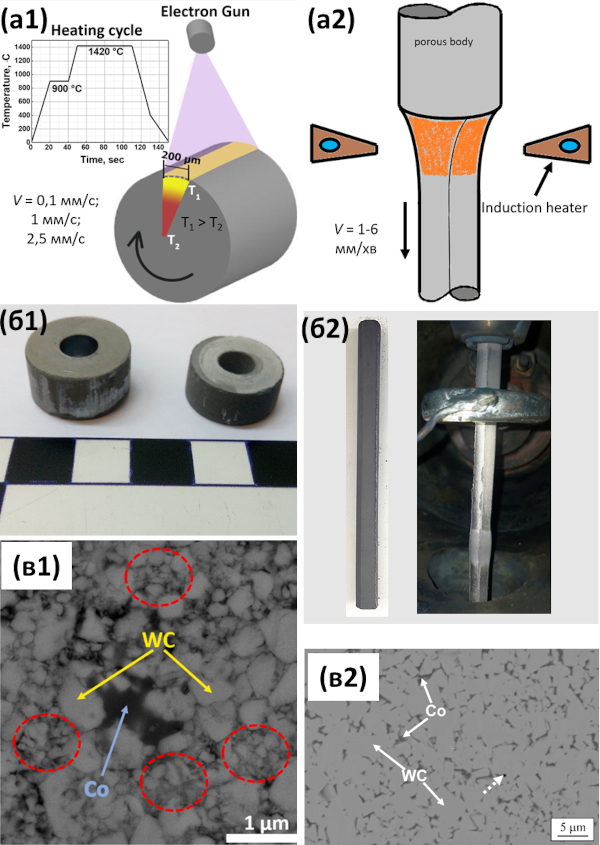

IMZ-19-04. Technologies of high-speed sintering of submicrograined cermet materials

TRL-3 Market and Economic Attractiveness Main Advantages (Strengths) of the Device Main Characteristics Marketing Readiness List of security documents for intellectual property rights: Developer Information What is Needed to Promote the Device

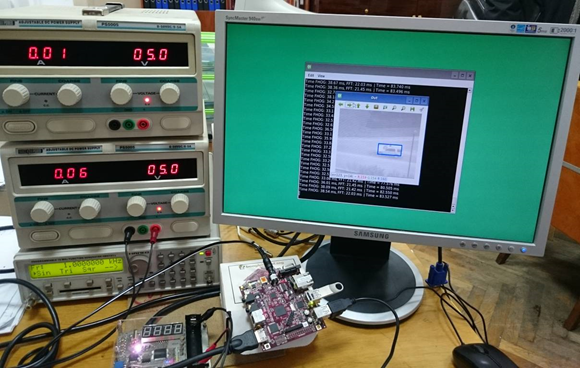

FEL-14-02. Portable system for automatic tracking of objects on video sequences

TRL-3 Market and Economic Attractiveness The development can become the basis for creating inexpensive up to $100 consumer and up to $500 industrial systems that require tracking of moving objects on video sequences in real time (surveillance systems, robotics, monitoring equipment for scientific and medical purposes) Main Advantages (Strengths) of the Device Development is usually… Continue reading FEL-14-02. Portable system for automatic tracking of objects on video sequences

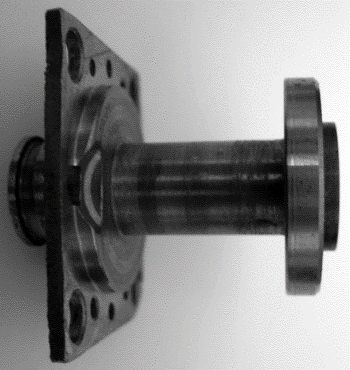

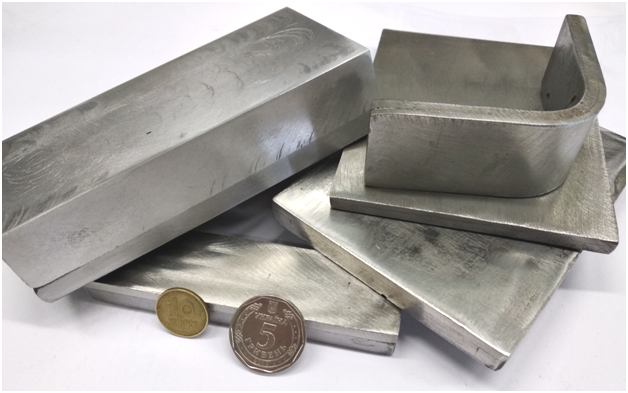

NN IMZ-01-01. A sample of an aircraft electro – pneumo -hydraulic valve body blank made by diffusion welding with thermocycling

TRL-6 The technology of composite soldering in a vacuum is intended for the correction of casting defects and the restoration after work of products made of heat-resistant alloys based on nickel, which are used in the fields of gas turbine construction, energy, chemical, aviation industry, etc. Market and economic attractiveness Increased productivity and efficiency of… Continue reading NN IMZ-01-01. A sample of an aircraft electro – pneumo -hydraulic valve body blank made by diffusion welding with thermocycling

NN IMZ-01-02. A sample of a metal-ceramic high-voltage hermetic conduit made by contact-reactive soldering in a vacuum

TRL-6 Ceramic vacuum seals are intended for use in mechanical engineering, energy, aerospace industry, instrument making and other industries Market and economic attractiveness The proposed Typical technology for the production of metal-ceramic assemblies of hermetic guides for electron beam guns in welding and spraying installations has successfully passed the test and manufactured products The optimized… Continue reading NN IMZ-01-02. A sample of a metal-ceramic high-voltage hermetic conduit made by contact-reactive soldering in a vacuum

NN IEE-18-01. Mobile protective screen against optical radiation for non-stationary workplaces of welders

TRL-2 The mobile protective screen (MZE) for non-stationary workplaces of welders is designed to protect other workers who are near the welder’s workplace and do not have individual or collective protection from excessive optical (ultraviolet and visible) radiation of the welding arc. Market and economic attractiveness As a result of tests in production conditions, the… Continue reading NN IEE-18-01. Mobile protective screen against optical radiation for non-stationary workplaces of welders

NN IMZ-02-01. Environmentally friendly molten fluxes

TRL-8 Fluxes: AN-69 environmentally friendly molten flux for surfacing low-, medium- and high-alloyed steels (TU U 24.6-05416923-096:2008) ANK-45 environmentally friendly agglomerated flux for surfacing low-, medium- and high-alloyed steels (TU U 24.6-05416923-095:2008) AN-44 environmentally friendly molten flux for welding low-carbon and low-alloy steels ANK-73 environmentally friendly agglomerated flux for surfacing (TU U 24.6-05416923-101:2011) Market and… Continue reading NN IMZ-02-01. Environmentally friendly molten fluxes

NN IMZ-13-01. Highly effective technologies for manufacturing bimetals using laser and combined processes

TRL-6 Market and economic attractiveness The economic expediency of using the proposed methods of production of bimetallic materials is: in significant and rational saving of material and energy resources; reduction of the specific cost of used production areas and labor costs; the possibilities of optimizing the choice of the most effective method of manufacturing bimetals.… Continue reading NN IMZ-13-01. Highly effective technologies for manufacturing bimetals using laser and combined processes