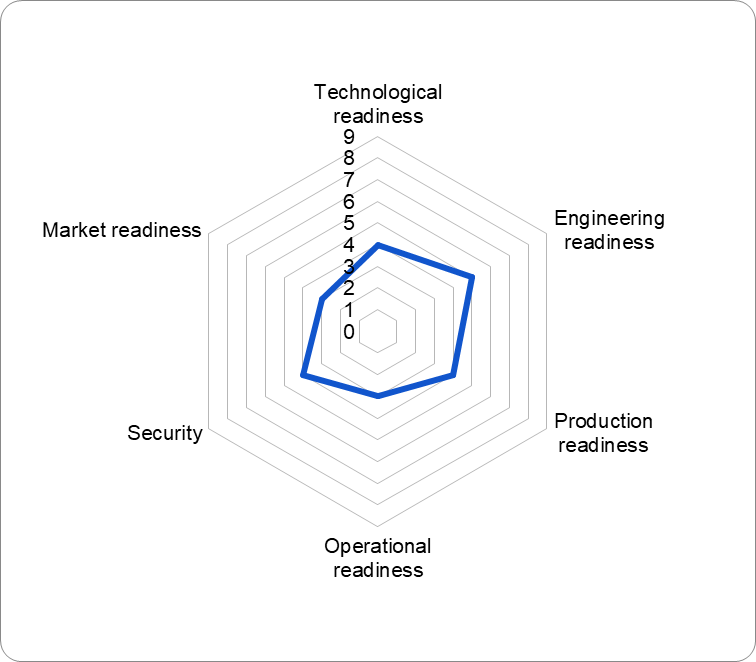

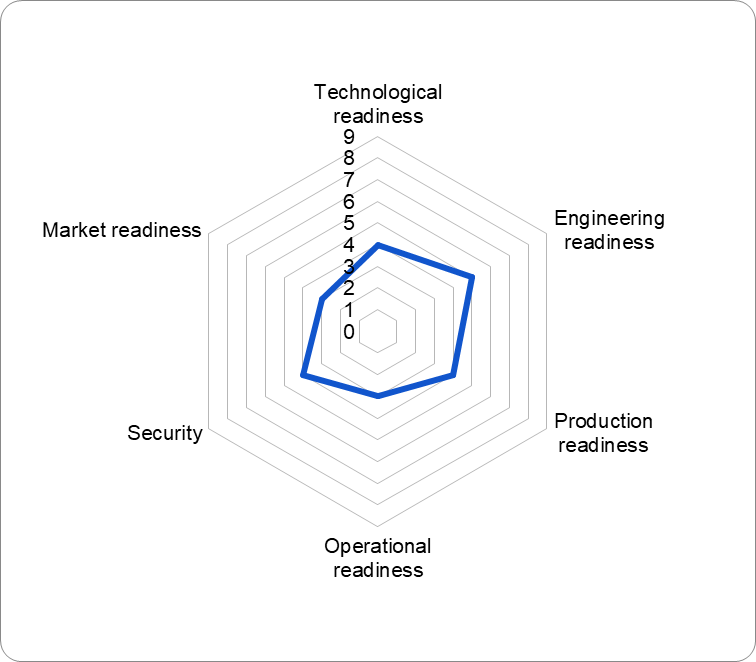

TRL-4

The development is intended for disconnecting three-phase asynchronous electric motors to avoid their failure in emergency situations:

- disappearance of supply voltage in one of the phases;

- violation of the phase sequence;

- an increase in the current consumed by the electric motor in one or more phases above the permissible value;

- increasing the asymmetry of the phases of the supply voltage beyond the permissible level;

- delayed start of the electric motor – the starting current does not decrease during the controlled time;

- an increase in the transient resistance of contacts in power circuits, automatic

Market and Economic Attractiveness

- The new quality is obtained thanks to software and hardware tools

- Functional capabilities of the device allow you to use it as a controller, for example, to turn off the electric motor when it goes into idle mode (pump electric drive, etc.)

- This device also supports blocking the next start of the electric motor after its emergency shutdown

- The device can be used to control other three-phase electric consumers:

- synchronous electric motors;

- transformers and other consumers that require protection against emergency modes. machines, starters, etc.

Main Advantages (Strengths) of the Device

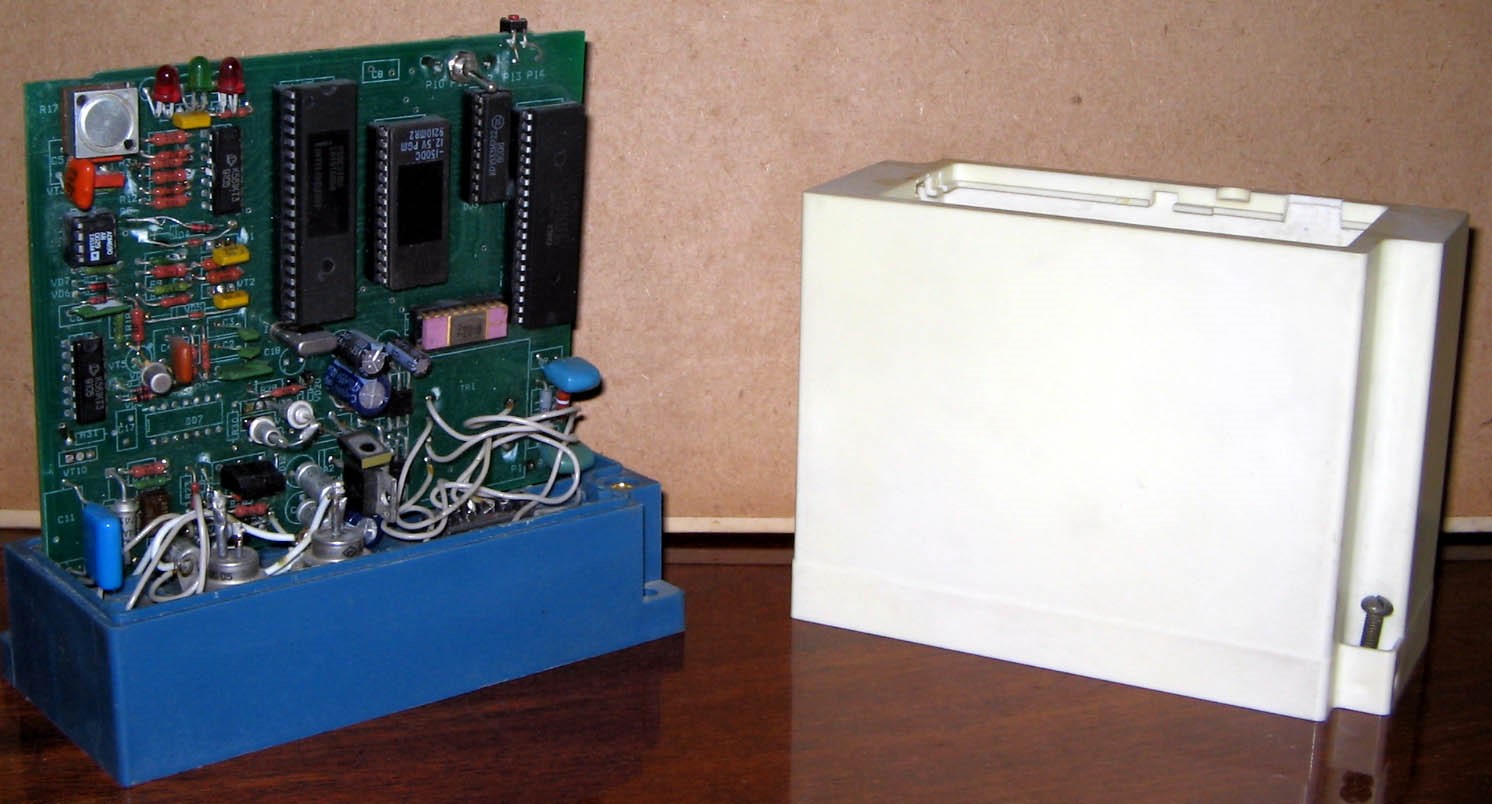

- The device consists of an electronic unit of three sensors for measuring the load current in the phases of the electric motor; indication of working and emergency modes is carried out with the help of LEDs, the output circuits of the device are connected to the circuit of the starter coil of the electric motor

- Control of the electric motor starter is non-contact;

- The device is a self-learning microprocessor system for direct control of a three-phase electric motor

- Manual input of information is not required for the protection device, this operation is performed automatically in learning mode at the first start of the electric motor

- Disconnection of the electric motor in case of overload is carried out with a dependent time delay, which depends on the value of the overload and varies within wide limits, which allows to reduce the number of emergency disconnections of the electric motor due to selective action during protection

Main Characteristics

| The supply voltage of electric motors | up to 1000 V |

| The rated power of the electric motor connection ranges | from 1.2 to 200 kW |

| The permissible value of the unsymmetry of the supply voltage phases | 10% |

| Uncontrolled acceleration time of the electric motor | up to 4 seconds |

| Rated starter coil voltages | 660, 400, 230, 127, 110, 60 or 36 V |

| The supply voltage of the device | 230 V at a frequency of 50, 60 Hz |

| Voltage deviation | from -15% to + 10% of the nominal value |

| Power consumption | 5 VA |

| The nominal load current of the switching device (starter coil) | 4,0 A |

| The minimum tripping time in case of overload | 0.1 sec |

| The device is operable in closed rooms at temperatures | from – 100C to + 500C |

| The device is operable in closed rooms with an ambient humidity | of 80% at + 350C |

| Operation mode | Continuous |

| The weight of the device without sensors | does not exceed 0,6 kg |

| The overall dimensions of the electronic unit | 140x140x60 mm |

Marketing Readiness

- The laboratory sample has been tested

- The mode of experimental production is implemented

- The basic production technology is defined and tested

- The technical requirements for the product have been clarified

- The strategy for the protection of intellectual property is formulated

- The competitive environment is defined

Developer Information

What is Needed to Promote the Device

Financing