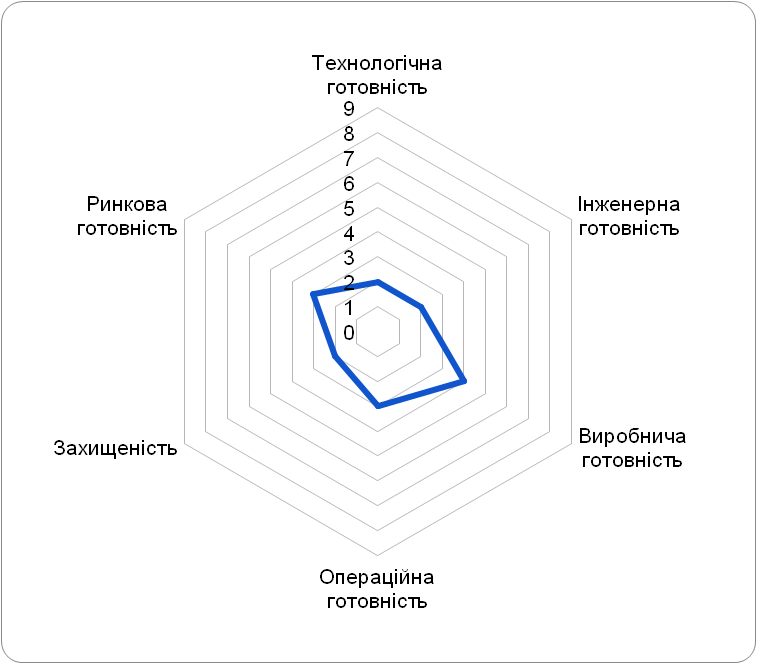

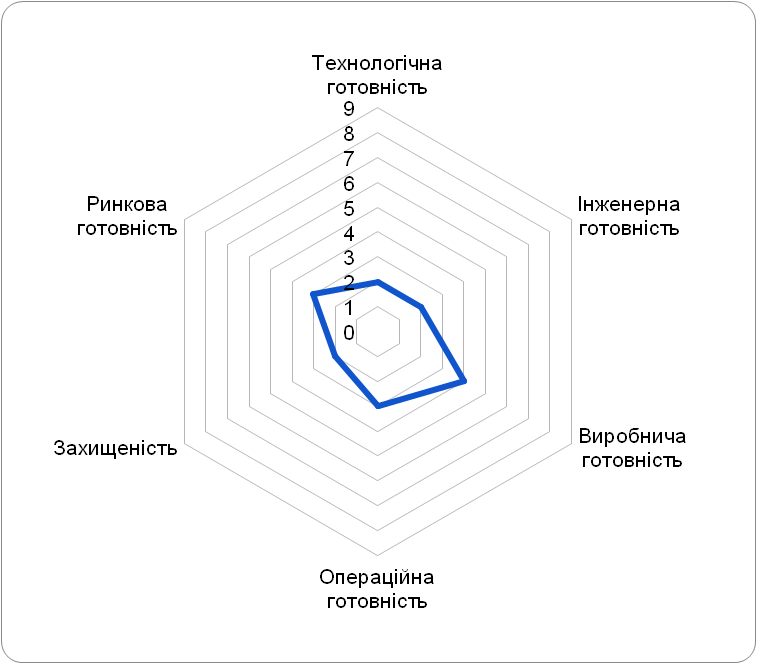

TRL-2

Market and Economic Attractiveness

- The implementation of the proposed solutions provides an increase in energy efficiency by 5-15% and an increase in resource by 20-40%, guarantees reliability and optimality of operation in production conditions.

Main Advantages (Strengths) of the Device

- The scientific and technical level of the work performed corresponds to the world level and exceeds it in certain indicators.

- The obtained new scientific and applied scientific results have value for the world and domestic science since the theory of electromagnetic and thermal processes was first developed in terms of calculating dynamic and interrelated electromagnetic and thermal fields in a three-dimensional inhomogeneous medium of complex configuration under conditions of nonlinear and non-stationary properties of materials.

- https://www.yuzhcable.info/cat/40

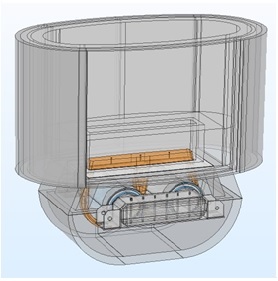

Main Characteristics

- The regularities of the distribution of the three-dimensional thermal field on the housing and the electric power characteristics of the operating modes of the industrial induction plant for the production of ultra-pure copper wire rod depending on the current state of thermal insulation are obtained.

- A method for calculating three-dimensional non-uniform electromagnetic and thermal fields with strong mutual connections in nonlinear media has been developed.

- Practical recommendations have been developed for increasing the resource and electrotechnological efficiency of installations by adjusting operating modes and improving the methodology for diagnosing the current state aimed at minimizing the maximum values of temperature, its gradients in local areas of thermal insulation and the dimensions of such areas.

- The main advantage of the improved technique for diagnosing the technical condition of induction plants is the ability to determine the configuration of liquid metal leaks in the internal areas of thermal insulation inaccessible for observation.

The developed recommendations were successfully implemented, which gave a number of positive results:

- The temperature on the housing of the induction furnace is reduced by 20 ° C (the actual temperature is not more than 110 ° C compared to 130 ° C with the new thermal insulation in the classic version);

- The specific power consumption per 1 ton of copper wire rod production was reduced (by 5% relative to the starting values of the new thermal insulation and on the order of 15% relative to worn-out thermal insulation before stopping the furnace);

- Improved working conditions of working personnel during furnace maintenance;

- The purity of the copper rod is improved, that is, the percentage of impurities is reduced.

Marketing Readiness

- Scope defined

- Analysis of the effect of the product on the entire system was carried out

- Basic production technology defined and tested

- Product specification clarified

- Patent analysis performed

- Competitive environment defined

List of security documents for intellectual property rights:

- Utility model patent No. 150917. Three-phase two-bridge compensation converter/Inventors: Boyko V.S., Dzigunenko I.A.; published 04.05.2022, Bulletin No. 18.

- Utility model patent No. 148297. Three-phase combined compensation converter/Inventor V. Boyko; published 21.07.2021, Blvd. No. 29.

- Utility model patent No. 146791. Three-phase cascade-bridge compensation converter/Inventor Boyko V.S.; published 17.03.2021, Blvd. No. 11.

- Utility model patent No. 147874. Three-phase two-bridge parallel type compensation converter/Inventor V. Boyko; published 16.06.2021, Blvd. No. 24.

Developer Information

- Research team FEA-01. Theory of unsteady electrophysical processes in energy.

- Research team FEA-02. Electrical control systems under conditions of uncertainty of the mathematical model of the object.

- Research team FEA-03. Compensating type electric energy converters.

What is Needed to Promote the Device

The cost of the project is about 1.5 million UAH, the implementation and payback periods are 1-2 years and 3 years, respectively.