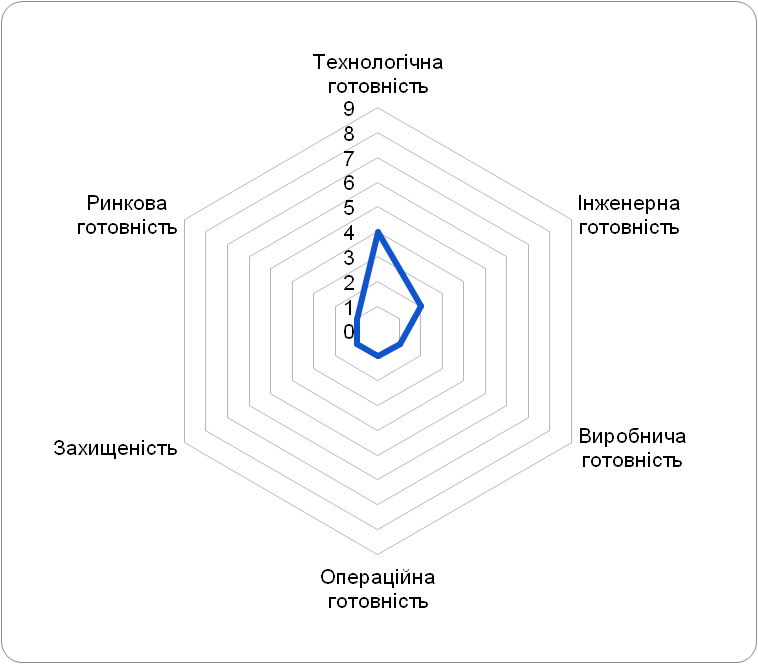

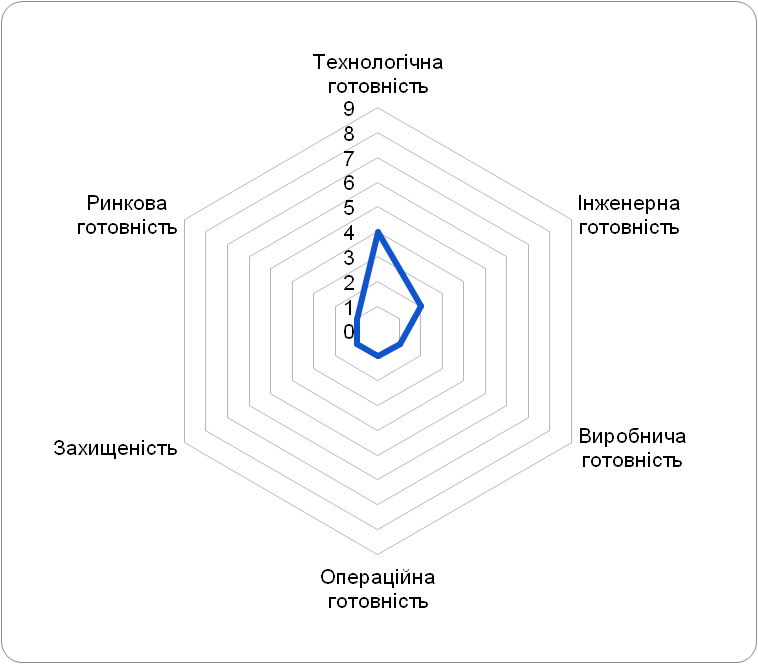

TRL-4

Technology tested in the laboratory

Available laboratory prototype

Market and Economic Attractiveness

- High competitiveness and the need to replace hydraulic shock absorbers as pollutants of the natural environment in the face of growing environmental requirements.

- High specific dissipation energy of external mechanical action with subsequent possibility of damper miniaturization.

Main Advantages (Strengths) of the Device

- High specific energy intensity of the dissipation process (5-50 J/cm3);

- Max workload can exceed traditional analogues without loss of workability;

- Providing passenger comfort and increasing the life of the mechanical parts of the car by reducing and stabilizing efforts in response to mechanical disturbance from road obstacles;

- Ensuring reliable adhesion of the wheels to the road while maintaining maximum comfort for passengers;

- Constant force on the vehicle body in a wide range of speeds and frequencies of interference on the road.

Main Characteristics

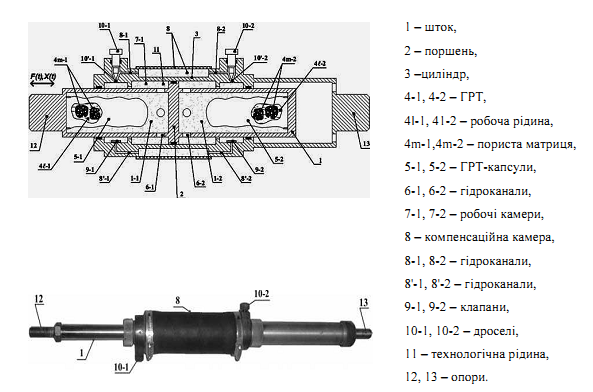

- Thermomolecular damper of automobile suspension with new heterogeneous working medium:

| Shock absorber operation amplitude | +/- 84 mm |

| Operating force on shock absorber | 1 kN |

| Shock absorber operating frequency range (compared to 4 ÷ 6 Hz for traditional hydraulic shock absorber) | 1-22 Hz |

| Required amount of heterogeneous working medium (instead of 1000 ÷ 1500 cm3 of technical oil) | 20 ÷ 25 cm3 |

Marketing Readiness

- Laboratory sample tested

- Analysis of the effect of the product on the entire system was carried out

- Basic production requirements are formulated

- Basic business process diagrams are defined

- Initial benefit and risk assessment completed

- Utility evaluation performed

Protection of intellectual property

- V.A Eroshenko, https://doi.org/10.1243/09544070D0150

- V.A Eroshenko, I.Piatiletov, L.Coiffard, and V Stoudenets, https://doi.org/10.1243/09544070D0160

Developer Information

- Research team NN IATE-18. Thermomolecular energy

What is Needed to Promote the Device

Financing for the development of pilot designs and their introduction into industrial production