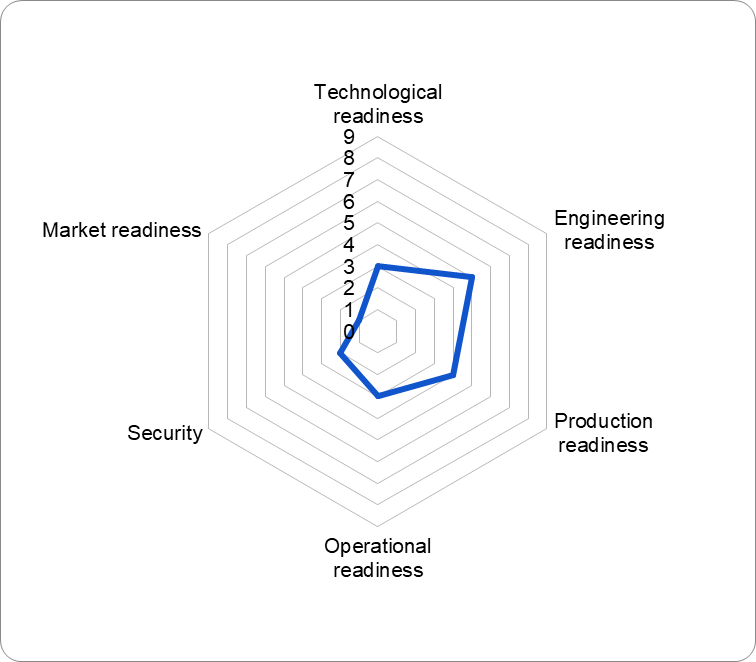

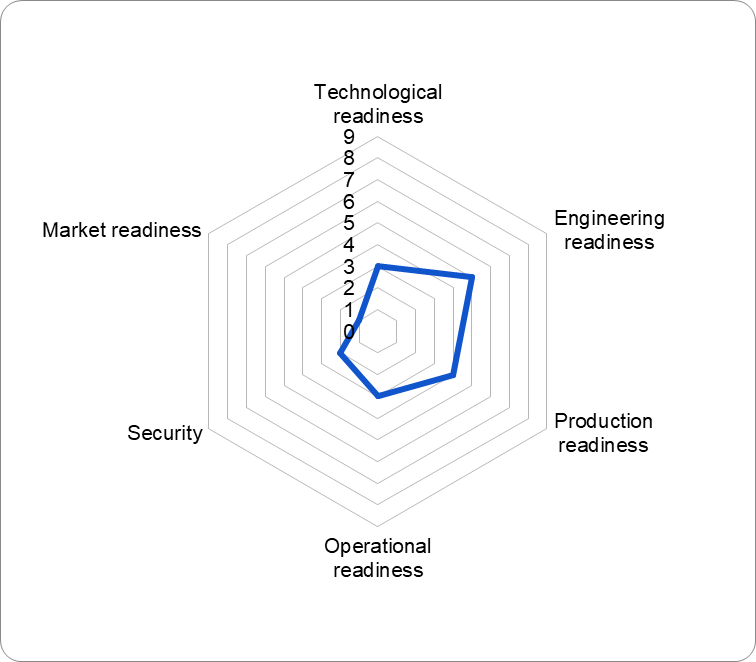

TRL-3

Market and economic attractiveness

- Reduction of production preparation time and costs due to the use of computer-integrated systems for designing and manufacturing complex shaped surfaces based on modern molding processes

- The use of a laser for the formation of shaped surfaces allows you to avoid the use of heavy equipment, high-cost and metal-intensive stamping equipment, which significantly contributes to resource conservation and production flexibility

- Laser-formed structures have higher resistance to working loads, which increases their operational characteristics. When using existing methods of forming, it will allow to use all the reserves that are included in them and to use them more rationally

The main advantages (strengths) of the development

- Laser forming is a non-contact, flexible process that is easily reconfigurable, does not require heavy metal-capable equipment and tools, and allows the formation of hard, elastic materials and brittle materials.

- Among the thermal methods of forming, laser forming is advantageously distinguished by the fact that the laser beam, as a heat source, is stable, dosed and can be clearly positioned

Main characteristics

- Processing without mechanical contact.

- The possibility of forming shelves smaller than 3 mm.

- Increased (by 10-15%) rigidity of structures.

- The possibility of forming hard, brittle materials.

Ready state

- The fundamental concept is formulated

- Requirements for engineering resources are defined

- The basic requirements for production have been formulated

- Schemes of basic business processes are defined

- An initial assessment of benefits and risks has been completed

- The evaluation of usefulness has been carried out

Information about developers

What is needed to promote development

- A laser of continuous action with a power of 2-3 kW

- 4x coordinate manipulator

- Surface shape control system based on triangulation