TRL-3

Market and Economic Attractiveness

- The developed fundamentals of the technology of high-speed sintering of hard-alloy materials and their subsequent scaling to production capacities (3-6 months) will make it possible to carry out import substitution of a wide range of products from hard alloys: wires for drawing wire (production of welding electrodes); cutting tools (non-sharpened carbide plates), as well as start the production of carbide armor-piercing cores.

- In a war with Russia, hard-alloy armor-piercing cores are a strategic military object that can be produced only in Ukraine. One armor-piercing cartridge costs from 500 to 1500 UAH. The line will make it possible to produce millions per year, which can be sold abroad. The launch of high-speed sintering technology will reduce electricity costs by more than 10 times. Simple calculations show that saving only energy resources allows you to save about 1.2 million UAH per year on the production of only hard alloy cores.

Main Advantages (Strengths) of the Device

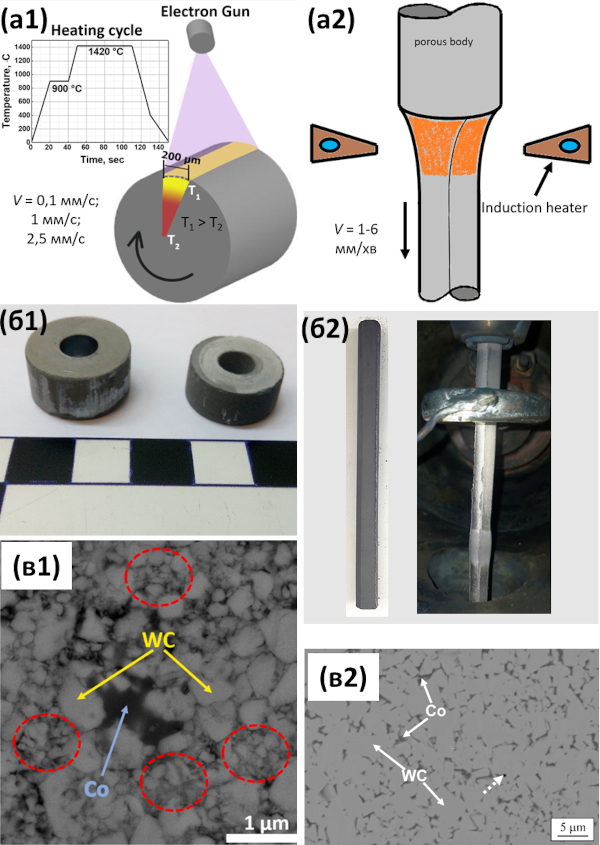

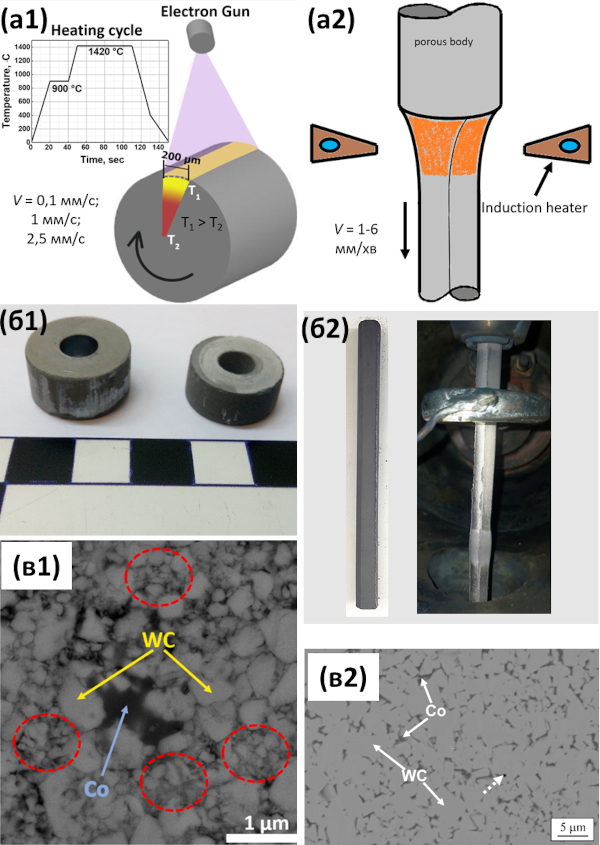

- Formation of submicron structure due to chemical dispersion: grinding of tungsten carbide grains during sintering.

- Ability to ensure a high speed of the sintering process: up to 2 minutes per product.

- Possibility of improvement of sintering technology for obtaining products of complex shape.

Main Characteristics

- Hardness of finished hard alloys with cobalt content of 8% is 91-93 HRA

Marketing Readiness

- Mock-up sample made

- Integration interfaces defined

- Basic production technology defined and tested

- Product specification clarified

- Patent applications filed

- Utility evaluation performed

List of security documents for intellectual property rights:

Developer Information

- Research team ІMZ-19. Automatic control of electrical systems with different types of power generation sources

What is Needed to Promote the Device

- Investments that will put the technology into production