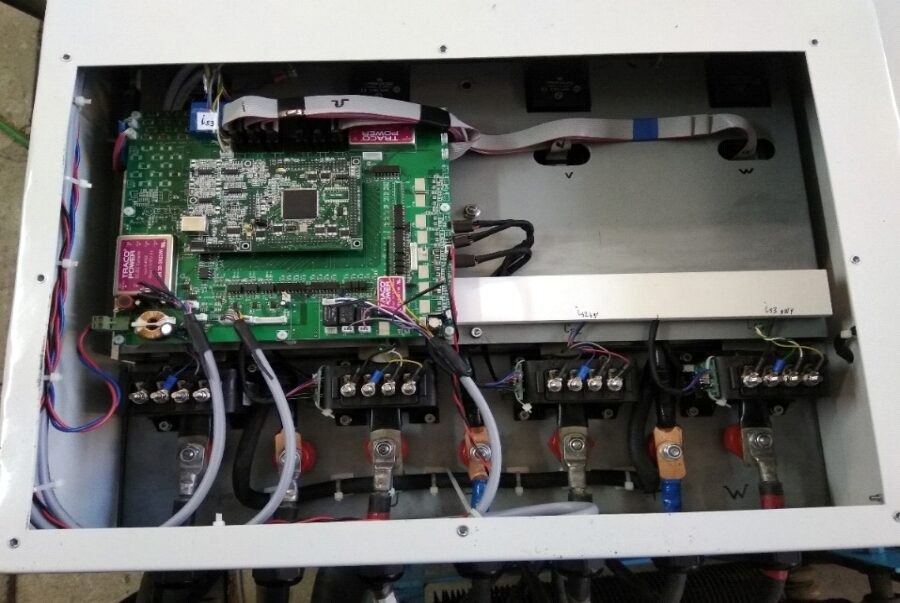

TRL-4 Market and Economic Attractiveness Main Advantages (Strengths) of the Device Main Characteristics Power 100 kW Input voltage 540 V Type of control Vector Marketing Readiness It is experimentally confirmed that the development fully meets the requirements for modern transport electric drives, which is confirmed by comparison with existing analogues. Developer Information Research team FEA-07.… Continue reading FEA-07-01. A new generation of highly efficient electromechanical systems of electric vehicles with vector-controlled engines that do not contain rare earth materials

ІMZ-22-01. A method for manufacturing titanium implants with developed surface

TRL-2 Market and Economic Attractiveness Main Advantages (Strengths) of the Device The disadvantages of the known methods of manufacturing metal implants are to obtain an insufficiently developed surface and the impossibility of significantly increasing the strength of the finished metal implant. Therefore, we propose to create a grid of cylindrical depressions on the surface of… Continue reading ІMZ-22-01. A method for manufacturing titanium implants with developed surface

ITS-04-02. An unmanned vehicle communication and control system of with increased resistance to intentional and unintentional interference

TRL-3 Market and Economic Attractiveness Modern unmanned vehicles, especially small-sized ones, are especially vulnerable to attacks on them, which lead to the destruction and interception of such devices. Therefore, architectural solutions for the construction of a control and communication system for UAVs have been developed, which are based on the use of advanced technologies of… Continue reading ITS-04-02. An unmanned vehicle communication and control system of with increased resistance to intentional and unintentional interference